About Advanced Manufacturing

Every Australian manufacturer has the potential to be advanced.

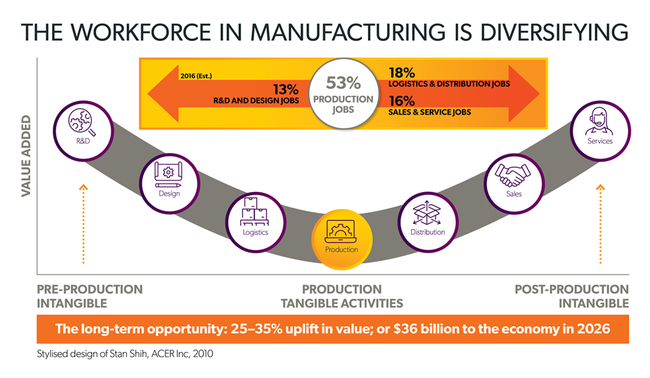

Manufacturing is undergoing a dramatic transformation, worldwide. Manufacturers are creatively diversifying their focus across different stages of the manufacturing process, both before and after goods are produced. As production activities are gradually being outsourced to developing countries offering cheap labour, more Australian manufacturers are recognising the need to compete on value rather than cost. Most commonly, this involves contributing innovative products, components or services within global supply chains.

Advanced manufacturing is not about what you make, but how.

AMGC finds that the most competitive manufacturing companies around the world were to have similarities in the way they succeed. These successful features include:

Advanced knowledge: continuously innovate with a high degree of R&D investment.

- See AMGC project High-Strength Aluminium Alloy on example of advanced knowledge

Advanced processes: focus on using state-of-the-art technology, become familiar with digitalisation.

- See AMGC project Customised Orthotics on example of advanced processes

Advanced business models: offer niche solutions, often highly customised and highly valuable.

- See AMGC project Remote Monitoring Software on example of advanced business model

Today, over 75 per cent of global trade is now in intermediate goods, for example, components and research. As a result, there is a growing market for advanced manufacturers that not only create finished products, but add value at every stage of and within the global supply chain.

For more information on how to become an advanced manufacturer, download our recent report Advanced Manufacturing: a new definition for a new era.