All Projects

Search for a project or use the filter below.

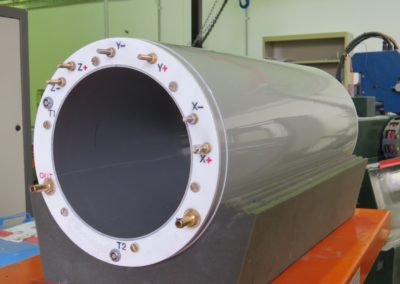

Commercialisation of lightweight, high-pressure composite hydrogen fuel vessel for use in Uncrewed Autonomous Vehicles (UAVs) and Hydrogen UAVs

Local production, testing and optimisation facility for the Smart Cathodic Protection Monitoring System

Commercialisation of oil-based Asparagopsis stable food supplement for livestock to reduce digestive-related methane emissions

Increasing recycling capacity and Australian manufacturing capability to manufacture greener infrastructure products

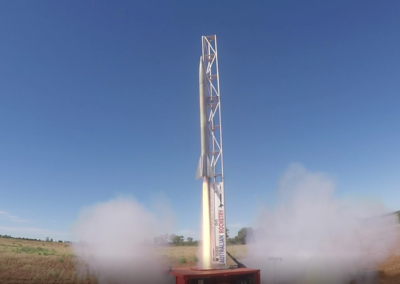

Project Rainbow Python: Development, testing, integration, and launch of a system for onboard processing of hyperspectral satellite data

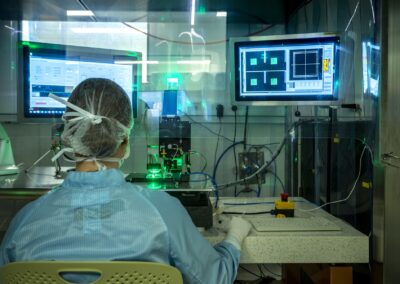

Bring to market MiCheck® Prostate, an algorithm driven in-vitro diagnostic test for aggressive prostate cancer enabling clinicians to assess the need for biopsy

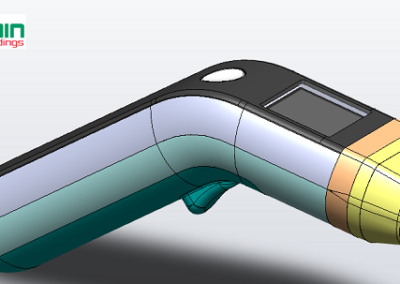

Design and manufacture of a handheld, cost-effective, whole-of-farm analyser for farmers, grain traders and agronomists

Hydrogenated water infusion machine to improve the health and commercial value of wild caught, and farmed finfish

Cost down all-in-one solar battery power converter and its commercialisation through Australian partners

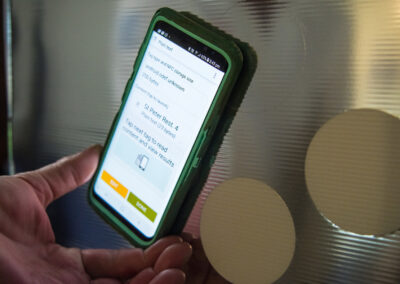

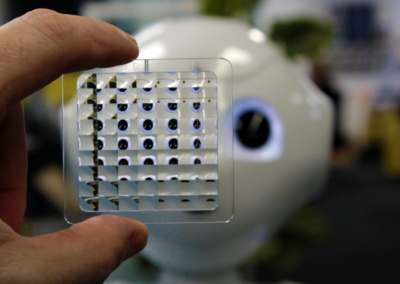

Manufacturing design and validation of portable rapid COVID-19 antigen testing unit (‘Virulizer’) and test strips for asymptomatic cases

Pre-production manufacturing design and validation of portable electromagnetic system for shallow conductivity profiling

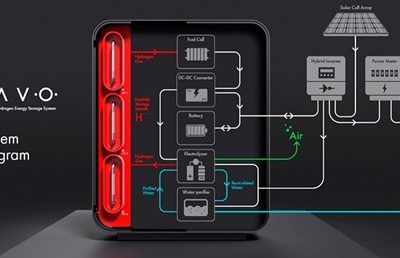

Set-up of a manufacturing facility and the commercialisation of the LAVO Hydrogen Energy Storage System

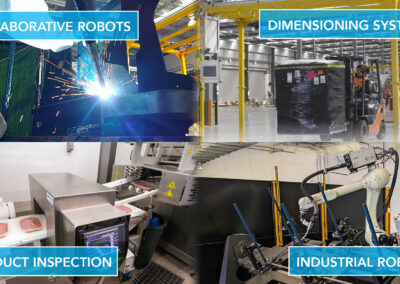

Validating ‘limbic scaffolding’ AI software to enable faster development and integration of cobots and robots

Validation of 3D-printing technology for mass-customisation of garments in the global clothing manufacturing industry

Augmented reality automated optical inspection (AugmentAOI) for printed circuit board (PCB) manufacturing

Development of an advanced industrial bolting system for improved safety and speed in the resource sector

Advanced manufacturing process validation for composite carbon fibre body armour and commercialisation through global value chain partners

On‐shore Manufacture of Notus Vivere Invasive Ventilators for Covid‐19 Patients based on Smiths Medical license.

Development, testing and production of a compressed air powered Intrinsically Safe UPS for underground mines and hazardous atmospheres.

Manufacturing of roll-to-roll supercapacitor electrode materials for powering next-generation IoT devices

Manufacture of Thermoplastic Poly-Urethane (TPU) top covers and Ethylene-Vinyl Acetate (EVA) base replacements

Development of a multifaceted bottom-up resin additive manufacturing platform for industrial applications

Validation of an innovative high purity alumina manufacturing process and verification of a commercial plant design

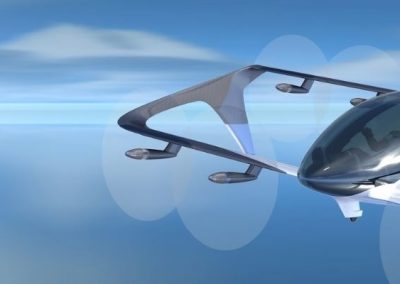

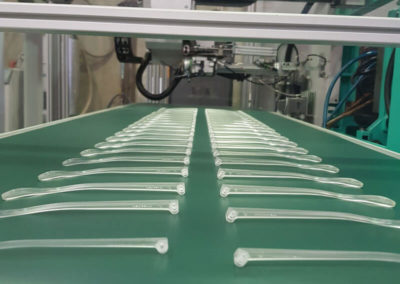

Filament wound and advanced composite structures for Vertiia – an electric vertical take-off and landing aircraft and Test flight of the assembled prototype

Design of a safe, hot-climate lithium-ion battery (LiB) module and associated automated advanced manufacturing production process

Industry 4.0 audit of 12 manufacturing SMEs to assessing their readiness to integrate digital technology into their manufacturing processes

Commercialisation of a prototype wear plate sensing system for the global mining industry via a servitisation business model

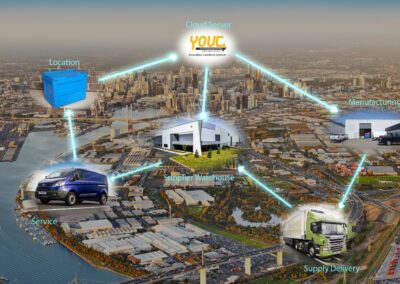

Developing a ‘Smart Factory’ conveyor table and motion control system for global logistics applications

Drawing value from solid wine waste by developing and demonstrating a small-scale pilot plant and designing an industrial-scale production plant

Industry 4.0 realisation via digitisation of existing SME manufacturing infrastructure and IIoT augmentation of manufacturing equipment

Development of a customised software package that facilitates the design and manufacture of complex components with a reduced occurrence of defects

Design project with the objective of reshoring the manufacturing of a customers plastic injection moulded bottle range to Australia

Upscaling of 36T’s manufacturing capability and commercialisation of a ‘multi-material’ bicycle wheel via global value chain partners

Implementing an automated production system to scale-up manufacturing of mass-customised prescription eyewear for a global consumer market

Production of pedestrian bridge and validation of new construction material for the global supply chain

A manufacturing process for bending corrugated metal sheets, and its commercialisation through global value chain partners

Industry 4.0 maturity program to raise the global digital supply chain readiness of Australian manufacturing SMEs